As the global trend of lightweight engineering accelerates, GBTECH—a national high-tech enterprise with over 20 years of experience in carbon fiber technology—is driving innovation not just in weight reduction but in performance-oriented composite solutions. Our focus on drones and automotive sectors reveals the full potential of carbon composites.

1. Truly Strong and Light — Redefining Structural Materials

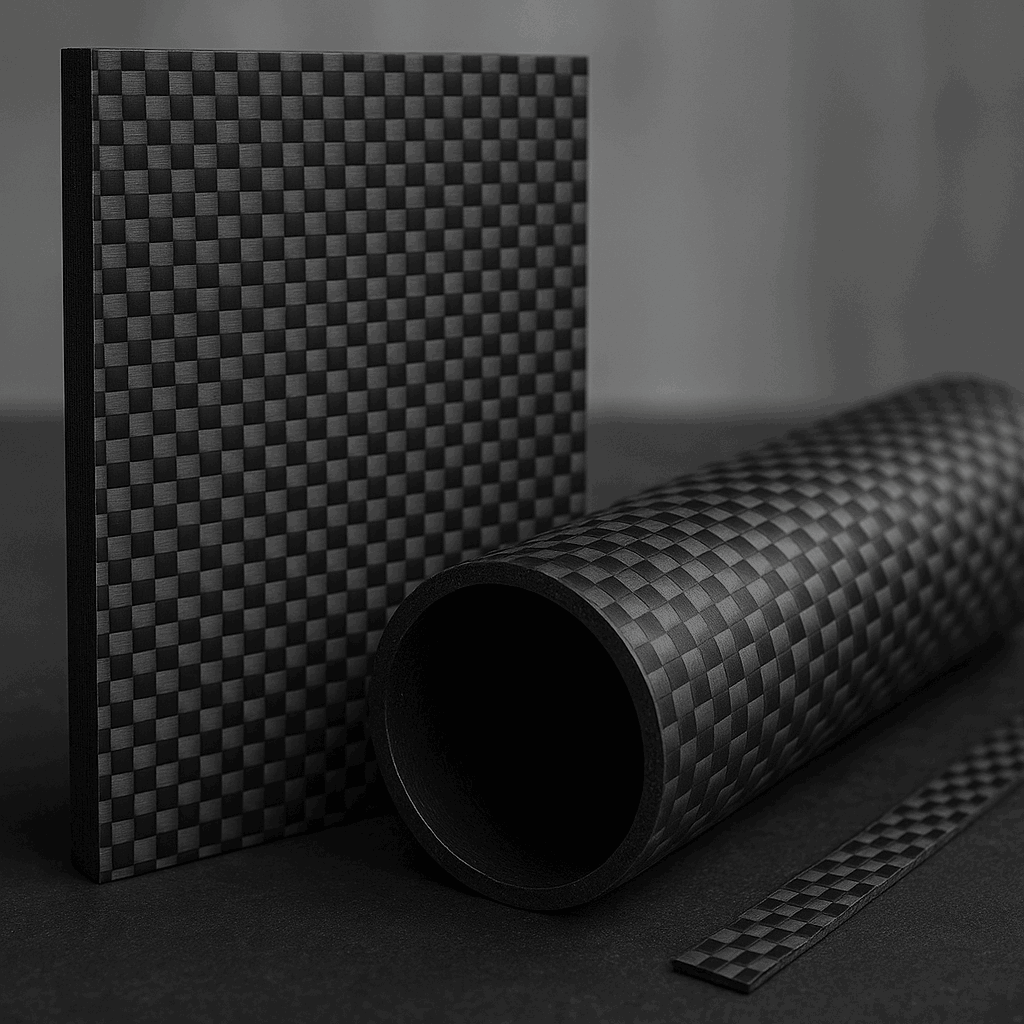

While conventional materials often trade off between strength and weight, GBTECH's composites deliver both. Our prepreg fabrics, pultruded tubes, and filament-wound parts offer:

- Strength-to-weight ratio >2x aluminum;

- Superior fatigue resistance in vibration-heavy use cases;

- Thermal stability over 150°C;

- Tailored layup angles for directional stiffness optimization.

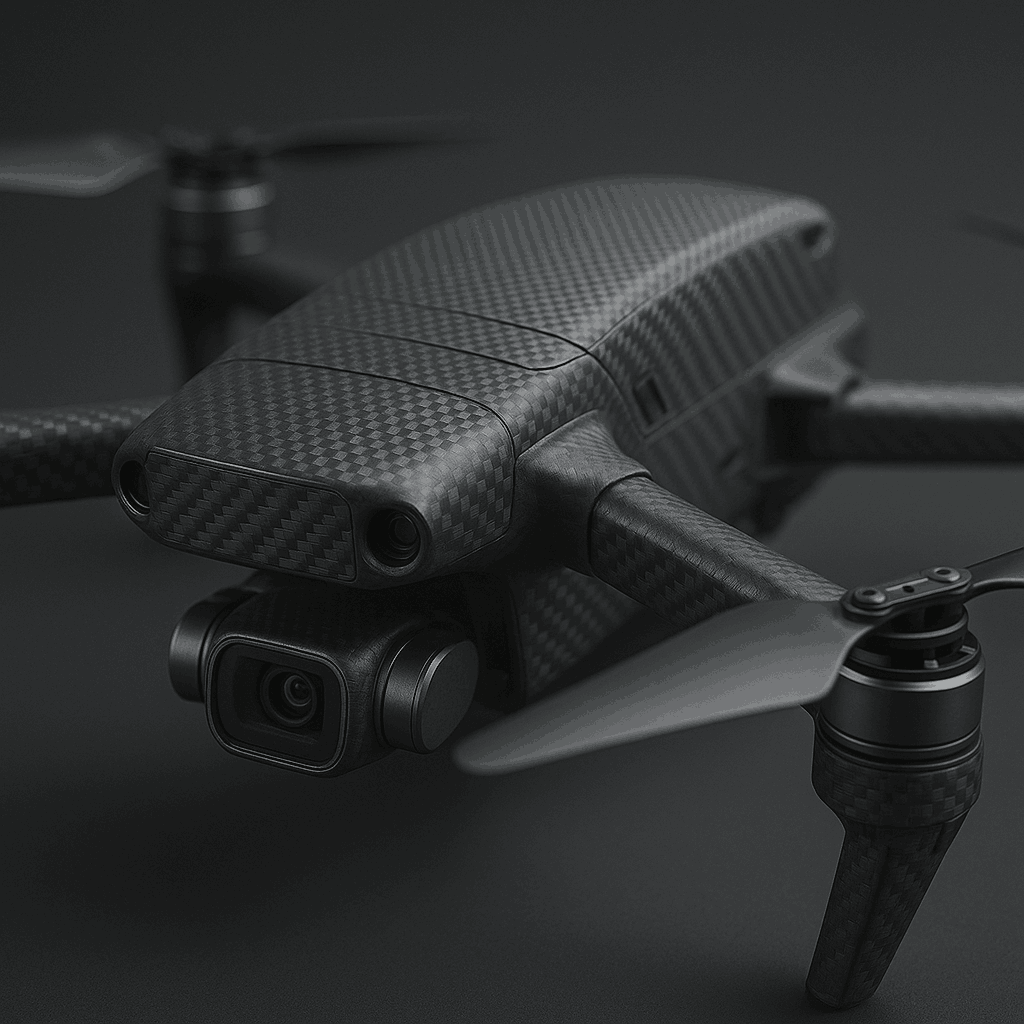

2. UAV Applications: Longer Endurance, Greater Stability

For both rotary-wing and fixed-wing UAV platforms, carbon fiber enables:

- Flight time increases by 30–50% through weight reduction;

- Superior vibration damping, enhancing sensor and camera accuracy;

- Dimensional stability under wind loads and temperature changes;

- Fast modular assembly, improving field maintenance efficiency.

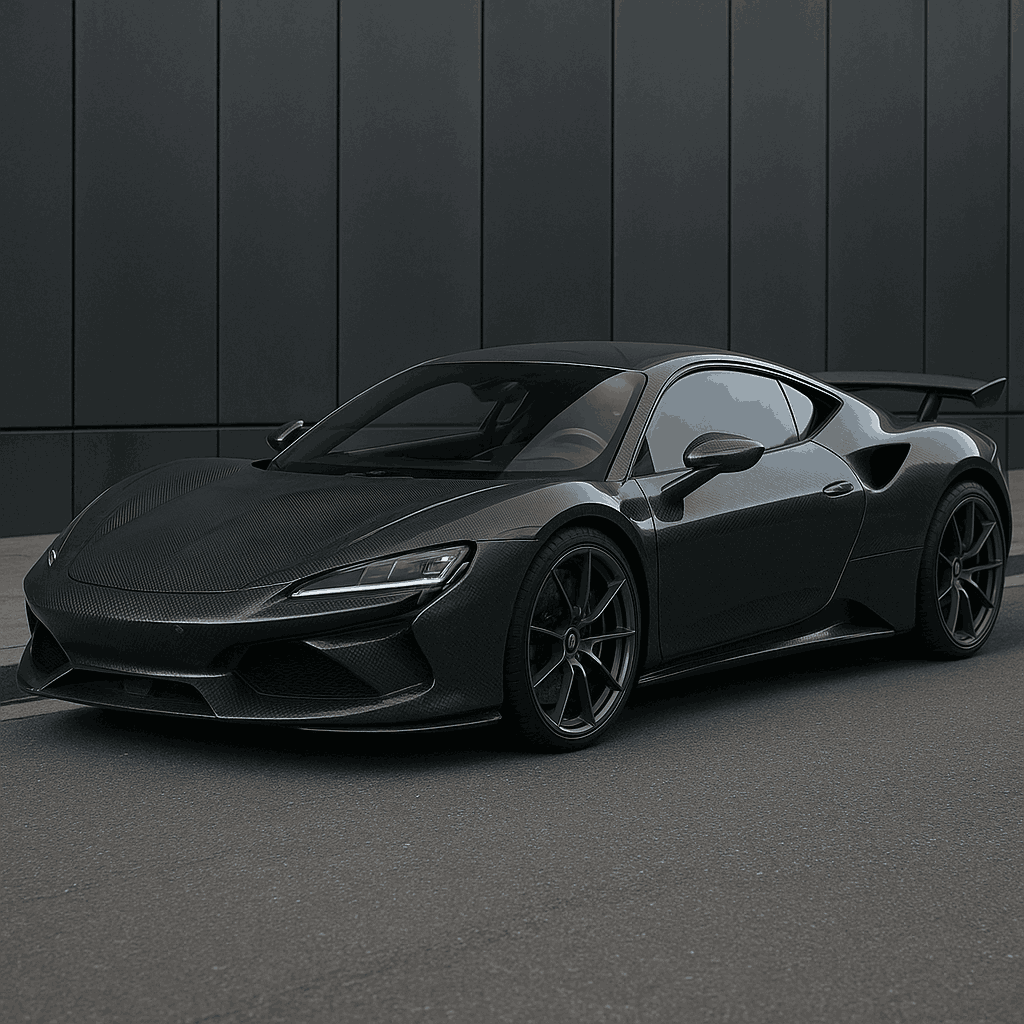

3. Automotive Lightweighting: Extend Range, Improve Safety

Carbon fiber plays a pivotal role in electric vehicles by lowering mass without compromising structural strength. GBTECH supplies:

- Battery housing structures with fire-retardant, insulating properties;

- Seat and door skeletons for energy absorption and safety;

- Exterior shells like hoods and mirrors with aerodynamic benefits.

Replacing steel/aluminum with composites can reduce vehicle mass by 100–200kg, delivering 8–15% more driving range.

4. From Fiber to Finish — GBTECH’s Full-Stack Production System

We operate a fully integrated carbon composite manufacturing chain:

- Fiber & resin prep;

- Multiaxial fabric and prepreg production;

- CNC cutting & automated layup;

- Forming via autoclave, pultrusion, filament winding, RTM;

- Complete QC with ultrasonic, thermal, and fatigue testing.