Green Manufacturing Leading the Future: How GBTECH Gains a Dual Advantage Through Low-Energy Carbon Fiber Processing

Under the dual-carbon strategy and the global trend of supply chain decarbonization, green manufacturing is no longer a corporate accessory—it has become a strategic threshold for future competitiveness. In the carbon fiber industry, while the material itself already offers lightweight and high-strength carbon-reduction benefits, its energy-intensive production process has long been a bottleneck and cost driver.

As a national high-tech enterprise with over 20 years of experience in composite materials, GBTECH is actively embracing low-energy manufacturing techniques, transforming the concept of “green materials” from a slogan into practical implementation to achieve both cost-effectiveness and environmental sustainability.

1. The Hidden Burden of Traditional Carbon Fiber Production

Carbon fiber is typically produced from polyacrylonitrile (PAN) precursor through a series of high-temperature treatments including stabilization (200–300°C), carbonization (1000–1600°C), and even graphitization (up to 3000°C). Though this process ensures outstanding mechanical performance, it brings three major burdens:

- High electricity consumption: Carbon fiber production consumes 1,500–2,500 kWh of electricity per ton.

- Concentrated carbon emissions: Even when avoiding fossil fuels, the thermal energy used indirectly contributes to emissions.

- Heavy capital investment: Equipment such as high-temperature furnaces, atmospheric controls, and exhaust purification systems result in large upfront costs.

Reducing energy consumption and simplifying production processes while maintaining performance has become the next critical challenge for global carbon fiber enterprises.

2. Emerging Green Processes and Their Transformative Potential

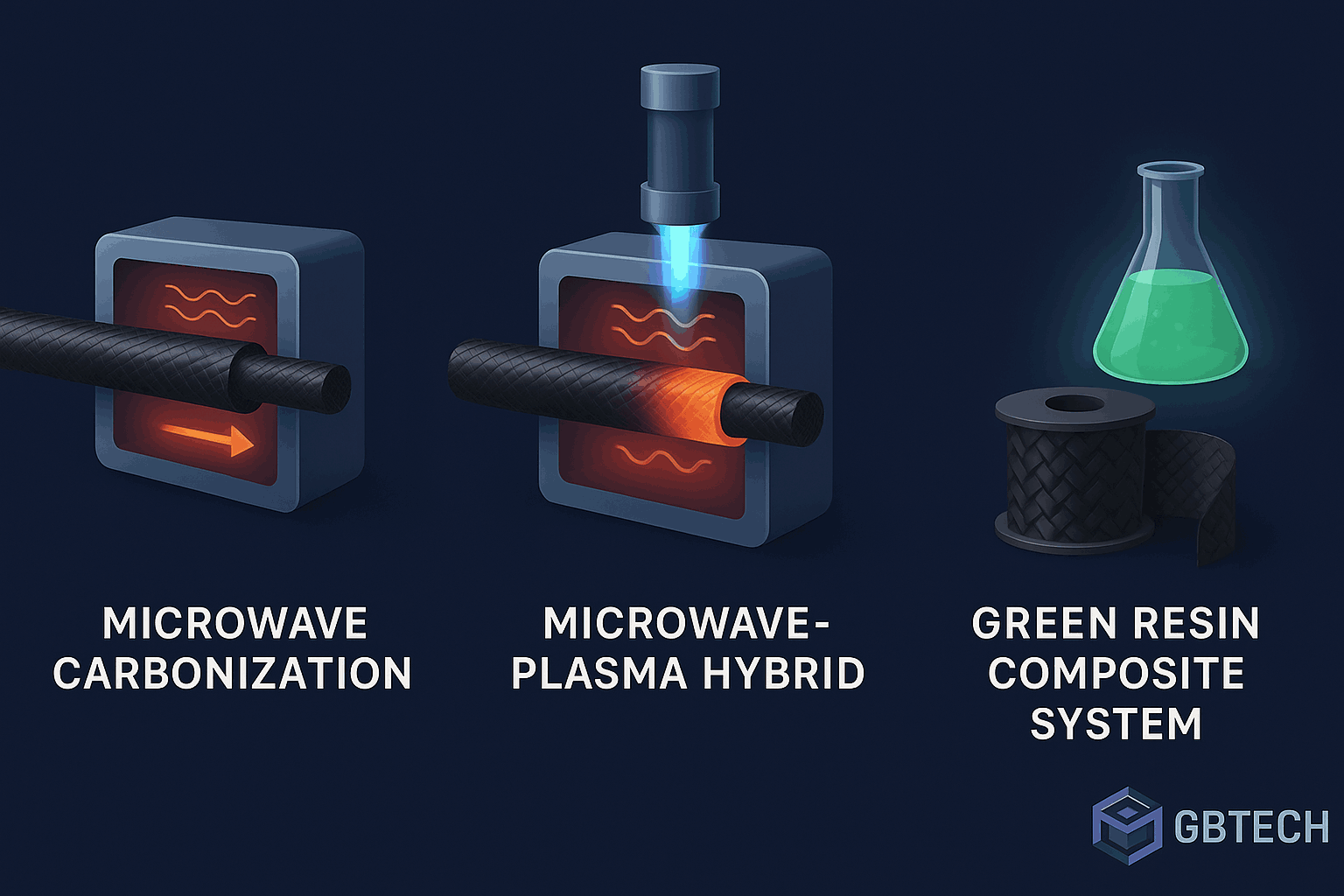

New-generation green carbon fiber technologies—such as microwave, plasma, and photothermal hybrid methods—are emerging and offer promising breakthroughs:

Microwave-Assisted Carbonization

- Heats the fiber internally for faster, more efficient thermal processing;

- Reduces energy consumption by 30–50% compared to conventional electric furnaces;

- Provides uniform heating, resulting in better product consistency.

Microwave-Plasma Hybrid

- Data from Ireland’s CARBOWAVE project shows energy savings of up to 70%;

- Enables low-temperature carbonization while reducing gas treatment requirements;

- Highly adaptable to large-scale automated production.

Green Resin Systems

- Incorporates bio-based epoxy and low-temperature curing prepreg materials;

- Reduces forming temperature from 180°C to 100°C;

- Shortens curing cycles and lowers overall energy usage.

These innovations are gradually overcoming commercialization barriers and providing viable technological options for process-driven manufacturers like GBTECH.

3. GBTECH’s Strategic Green Initiatives

As a vertically integrated carbon fiber composite manufacturer, GBTECH oversees the entire process—from raw fiber blending and prepreg production to molding and final testing. In response to green manufacturing trends, the company is focusing on three key strategies:

Process-Level Energy Optimization

- Retrofits high-energy equipment such as autoclaves and ovens with frequency control and zoned temperature regulation;

- Introduces modular microwave heating units for pilot-scale carbonization trials;

- Implements real-time energy monitoring and smart analytics on production lines.

Material Innovation

- Collaborates with universities and research institutions to develop low-temperature green resin systems;

- Launches the “Green Prepreg” series for environmentally demanding applications such as wind turbines, urban mobility, and interior construction;

- Expands research on bio-based materials and recyclable carbon fiber composites.

ESG and Low-Carbon Certification

- Promotes carbon footprint tracking systems for export products;

- Initiates ISO 14067 certification for carbon footprint evaluation;

- Explores cost-sharing models with clients based on energy and emission savings.

4. The Dual Advantage of Green Manufacturing

The essence of this dual-benefit model is not marketing hype, but the real reduction of energy data and certification infrastructure that make clients willing to pay a reasonable premium for 'greener materials'.

Focus Area | Cost Perspective | Environmental/Brand Perspective |

Reduced Energy Use | Lower power and water costs | Stronger green certification impact |

Improved Efficiency | Faster curing, shorter cycles | Less wear and reduced material waste |

Market Expansion | Enter green sectors like wind, EVs, architecture | Meet EU/US standards, boost competitiveness |

Policy Benefits | Access to subsidies and carbon credits | Gain government and industry support |

5. Conclusion: Green Processes as a Barrier, Not a Burden

In the next 3–5 years, the carbon fiber industry will undergo two major shifts:

- Clients will increasingly prioritize the environmental footprint of material lifecycles;

- Energy costs and emissions policies will directly influence project access and certifications.

In this context, companies that first achieve a closed-loop green production system will gain pricing power and global influence.

For GBTECH, green manufacturing is not a burden—it is a competitive moat, a value lever, and a path to long-term market trust.

We look forward to working with future-focused partners to combine “lightweight strength” with “sustainable stability,” and jointly shape the next era of carbon materials.