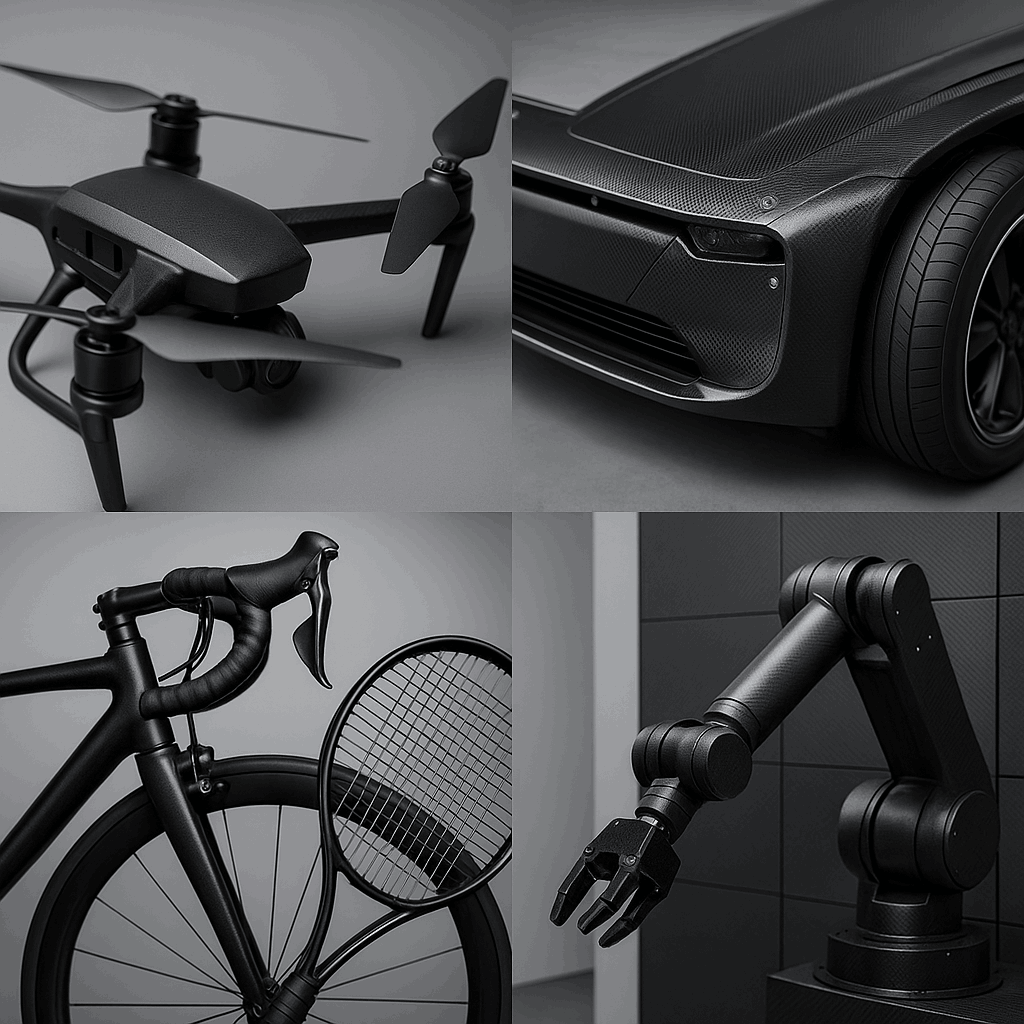

With the increasing application of carbon fiber materials in aerospace, automotive, sports equipment, robotics, and other industries, carbon fiber plates have become a key structural form.

However, due to different processing techniques, structures, and performance requirements, the market offers a wide range of carbon fiber plate types with significant performance differences.

As a national high-tech enterprise with over 20 years of experience in composite materials, GBTECH provides this guide to help users accurately select the right product for their needs.

1. Basic Manufacturing Process

Carbon fiber plates are typically composed of carbon fiber fabrics (e.g., plain, twill, or unidirectional) and resin matrices (such as epoxy or phenolic).

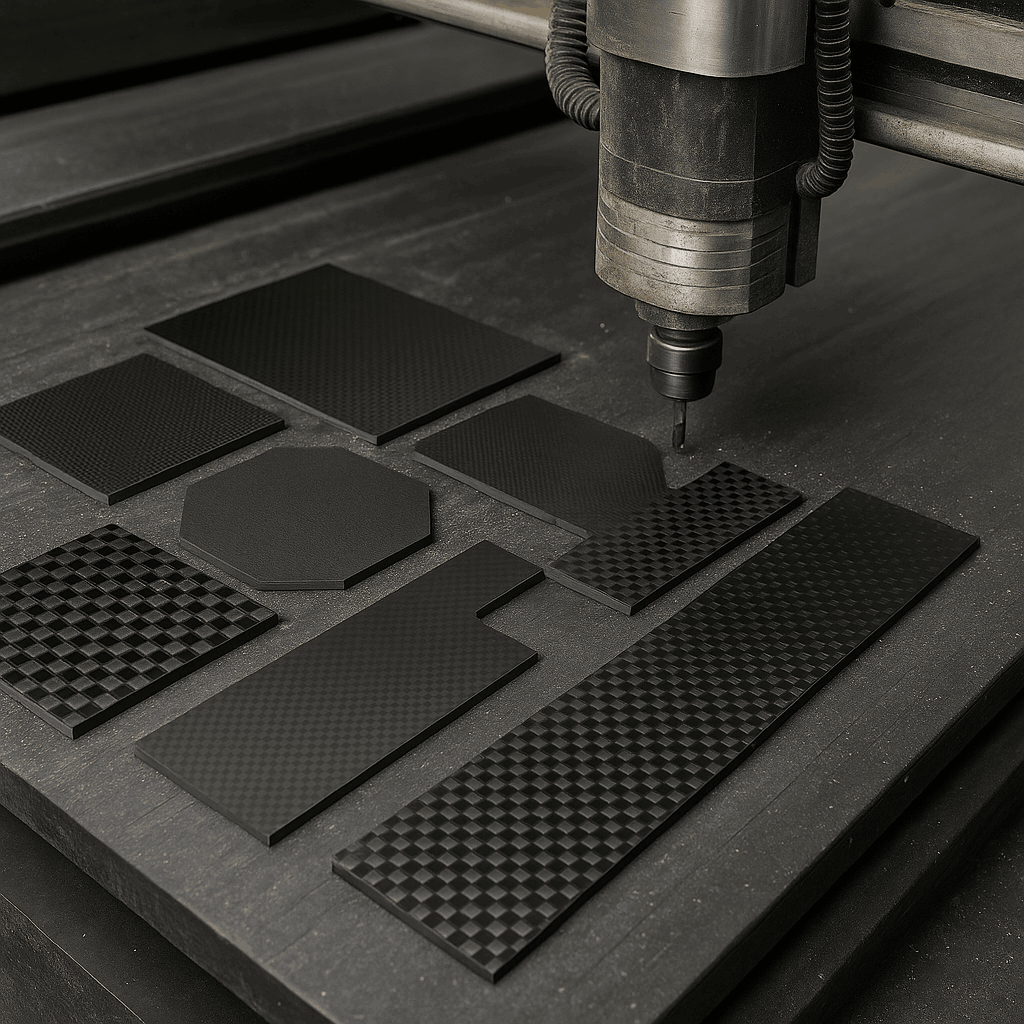

The standard production process includes:

- Prepreg or resin infusion

- Layering (manual or automated)

- Thermal curing (autoclave/hot press) or room temperature molding (RTM/vacuum bag)

- Post-curing and finishing

The fiber orientation, resin system, curing method, and interlayer configuration directly influence the mechanical properties, surface quality, thickness accuracy, and service life of the final product.

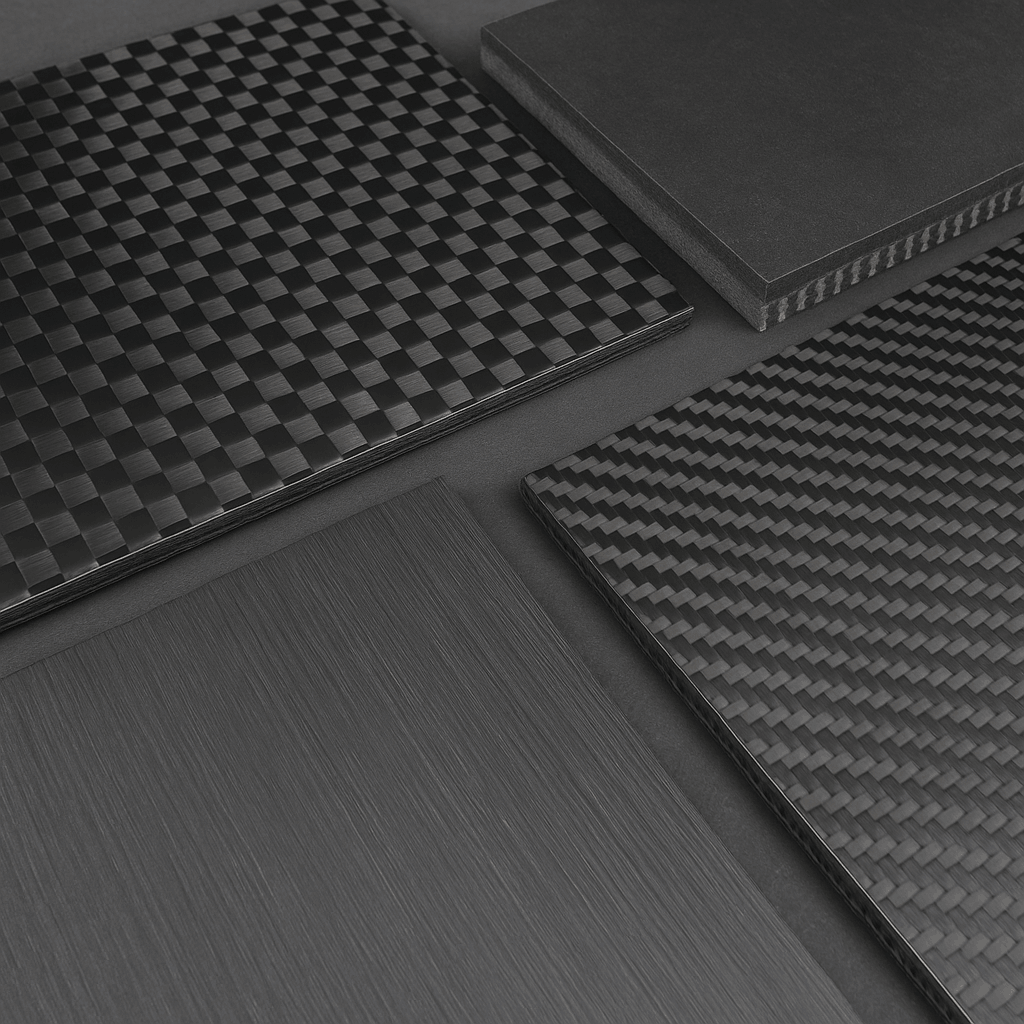

2. Common Carbon Fiber Plate Types and Their Differences

Unidirectional Plate: Maximum strength in a single direction; ideal for UAV blades, robot arms.

Woven Fabric Plate: Balanced strength across directions; used for decorative panels, vehicle covers.

Multiaxial Plate: Multiple fiber angles (0°/90°/±45°); suitable for EV chassis, wind blades.

Solid vs. Sandwich Plate:

- Solid: Fully carbon composite; high strength and stiffness.

- Sandwich: Foam or honeycomb core; lighter and vibration-absorbing; used in drones, seats.

Curing Process Types:

- Hot-pressed (Autoclave/HP-RTM): Aerospace and military; high precision but expensive.

- Room temperature molding (VARTM): Cost-effective for sporting goods and industrial components.

3. Other Differentiation Factors

- Resin Systems: Epoxy (stable), Phenolic (flame-retardant), Bio/Low-temp (eco-friendly).

- Surface Finish: Glossy, matte, sanded, anti-slip, or custom film.

- Thickness & Custom Size: 0.3mm to over 30mm, large format (e.g., 1000x2000mm).

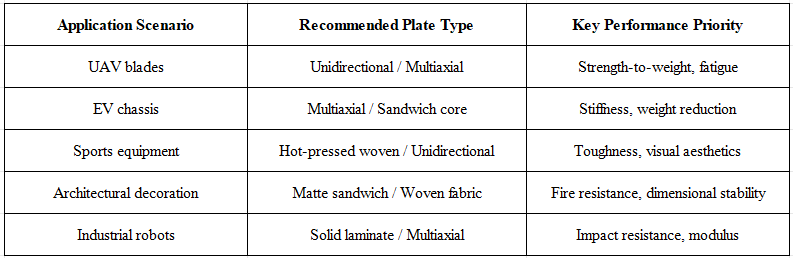

4. Application Scenarios

5. Conclusion

Despite the variety in form, all carbon fiber plates rely on the fundamental carbon + resin logic.

By tailoring detailed process parameters, structure design, and performance needs, GBTECH delivers customizable, cost-effective carbon fiber plate solutions.

Our advanced digital layering and thermal processing, combined with certified testing, ensure superior quality for cross-industry applications.

Contact GBTECH’s technical team for the best plate recommendation for your project.