GBTECH leverages carbon fiber composite technology to develop a new generation of boxing helmets that combine exceptional lightness with reliable impact protection and athlete comfort. These helmets are designed for professional training, club use and youth safety, emphasizing modular energy absorption, ventilation and maintainability.

1. Product Positioning

Use cases: Pro training edition, club training edition, youth protective edition.

Key selling points: ultra-lightweight, high-strength shell, customizable appearance (carbon weave / matte finish / color film), fast ventilation, modular removable liners.

Important note: This equipment reduces surface injuries but is not certified to prevent concussion or brain injury. Avoid medical claims in marketing.

2. Design Principles

Balanced shell stiffness: CFRP shell disperses local impact but must not be overly rigid to avoid transmitting energy to the head.

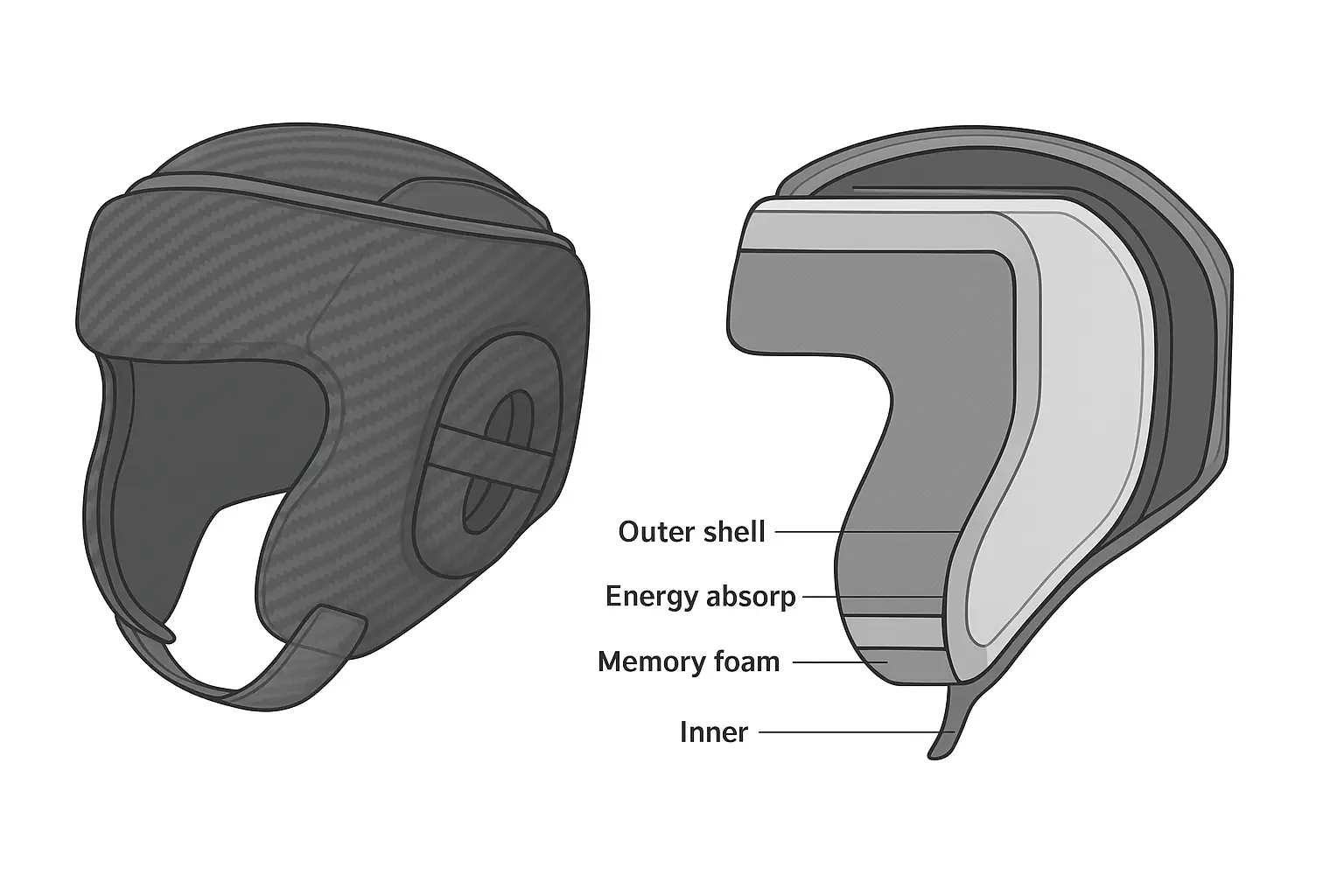

Layered energy-absorption system: Outer carbon fiber shell + EPP/EPS or PU foam core + memory-foam comfort layer.

Localized reinforcement: Replaceable or graded-density modules at temples, forehead, occiput and jaw.

Ventilation: Passive ducting and vents between shell and foam to reduce heat and sweat.

Modular maintenance: Removable, washable liners and replaceable energy modules.

3. Materials & Typical Structure

| Layer | Material | Typical Thickness / Notes |

|---|---|---|

| Outer finish | PU paint / film | ~0.1 mm — UV & scratch resistant |

| Outer shell | Prepreg CFRP or molded CFRP | 0.8–1.5 mm (regionally varied) |

| Bonding layer | Epoxy structural adhesive | Thin adhesive layer |

| Energy core | Multi-density EPP / EPS or TPU honeycomb | 20–30 mm (configurable) |

| Cushion | Memory foam | 3–10 mm for comfort & secondary damping |

| Liner | Antimicrobial moisture-wicking fabric | Removable & washable |

4. Innovative Features

Modular energy-absorber inserts for targeted protection and serviceability.

IMU / sensor port provision for optional impact monitoring and training analytics.

Passive ventilation channels integrated into internal architecture.

Use of recyclable EPP and eco-resin options to improve sustainability.

5. Manufacturing Roadmap

Prototype: Vacuum-bagged prepreg or hand-layup for functional prototypes and fit tests.

Validation: Produce 5–10 units for wear trials and laboratory impact testing.

Scale-up: Transfer to RTM or compression molding for stable, repeatable volume production.

Finish & assembly: Coating/film → liner & retention systems → QA and packaging.

6. Testing & Verification

GBTECH recommends independent laboratory testing including drop/impact tests on headforms (reference standards such as EN-type headforms), multi-impact durability, retention strap tensile tests, bond peel/shear tests, environmental aging (temperature, humidity, UV) and human fit trials. Typical target mass: ≤450g for ultralight, 450–600g for standard training models.

7. Example Product Range

StrikeLite — Pro: 1.2 mm CFRP shell + 25 mm multi-density EPP, ~420–480 g, sensor-ready.

GuardFlex — Club: CFRP/FG hybrid shell, 20 mm EPP, ~520–600 g, durable and cost-effective.

JuniorSafe — Youth: Glass fiber with local CFRP reinforcement, 18 mm EPP, ~380–450 g, adjustable fit.

8. Market & Launch Recommendations

Engage boxing federations and training facilities for field validation and endorsement. Publish third-party impact test reports and MSDS documents. Position StrikeLite as a high-end training product and GuardFlex/JuniorSafe as club/youth variants with clear labeling that the product does not claim medical protection from concussion.

WhatsApp

WhatsApp