Carbon fiber tubes are becoming essential in modern lightweight aircraft design. When replacing traditional D16T or AMG aluminum tubes in components such as ailerons, stabilizers, UAV frames or control surfaces, selecting the right manufacturing process is key to achieving optimal weight reduction, mechanical performance and production efficiency.

Filament winding uses continuous resin‑impregnated fibers, wound at programmable angles over a rotating mandrel and then cured. This method is widely used in aerospace and high‑pressure structural applications.

Exceptional mechanical performance — highest torsional, compressive and hoop strength due to continuous fibers.

Maximum weight reduction — fiber volume ratio up to 60–70%, enabling very high specific strength and stiffness.

Superior consistency — highly automated process ensures uniform wall thickness and fiber orientation.

Higher initial equipment cost.

Best suited for medium‑to‑large batch production.

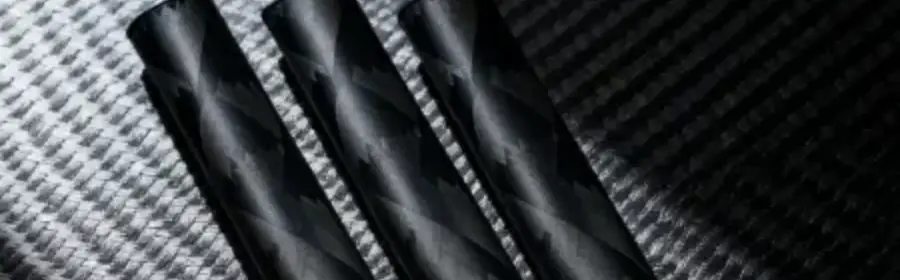

Roll wrapping uses pre‑preg carbon fiber sheets laid at designed angles, wrapped around a mandrel, vacuum‑bagged and cured. It is highly flexible and widely used for UAVs, sports equipment and custom aerospace parts.

High cost efficiency — ideal for small‑to‑medium batch production and customized components.

Excellent surface quality — smooth inner and outer surfaces using precision mandrels.

Perfect for long, thin tubes — ideal for aircraft control rods or tubes such as 23×1760mm.

Lower hoop strength than filament winding (can be compensated by 90° layers).

Possibility of a longitudinal seam if not optimized.

| Criteria | Filament Winding | Roll Wrapping |

|---|---|---|

| Mechanical Performance | ★★★★★ (Best for torsion & hoop strength) | ★★★★ (Excellent with proper layup) |

| Weight Reduction | ★★★★★ | ★★★★ |

| Cost Efficiency | Best for large batches | Best for small/medium batches |

| Consistency | ★★★★★ (Automated) | ★★★★ (Process‑dependent) |

| Design Flexibility | High | Very high |

• Best performance (primary load‑bearing aircraft components):

Filament‑wound tubes are the most reliable choice for stabilizers, ailerons and parts requiring maximum torsional and hoop strength.

• High‑value alternative (budget or moderate loading):

Roll‑wrapped tubes with optimized layup ([0° / ±45° / 90°]) offer excellent performance with better cost flexibility.

• Mixed application strategy:

Use filament winding for critical areas and roll wrapping for secondary structures to achieve the best balance of cost and performance.

Both manufacturing processes provide outstanding performance potential in aerospace applications. Filament winding delivers the highest structural strength, while roll wrapping offers unmatched flexibility and cost benefits. Selecting the right process depends on the structural load requirements, budget and production scale.

For technical consultation, custom tube design or OEM production, contact GBTECH — specialist in high‑performance carbon fiber composites.